ELECTROLYZER COATINGS

Platinum (Anode)

Typically platinum is used for hydrogen PEM water electrolyzer bipolar plates. Naco's platinum coating is thinner, denser and more homogeneous than those applied by conventional methods like electroplating. That allows to reduce platinum loading 10 – 40x at the same time ensuring required conductivity and corrosion protection.

Bimetallic nitrides (ICR Cathode)

Typically platinum is used for cathodes but new materials such as Naco's bimetallic nitride nano-coating can be applied to cathode side. This protects PEM water electrolyzer cathodes without extensive use of noble materials. It consists of three layers. The first provides good adhesion, the second (main) nitride layer prevents hydrogen diffusion and the few-nanometer top layer ensures stable conductivity.

Platinum for PTL

Naco Pt for porous transport layers pushes the boundaries on uniformity and platinum efficiency thanks to our proprietary high-speed magnetron sputtering technology. With a low platinum loading of 0.1 mg/cm² that significantly reduces costs, Naco Pt still delivers high conductivity and optimized electrochemical performance, ensuring reliable and efficient hydrogen production.

Oxides for Interconnects

For solid oxide systems, Naco Ox leverages our proprietary technology to create oxide layers that are 10 times thinner than conventional spray coatings, significantly enhancing conductivity and reducing resistance without compromising durability. With its ultra-thin profile, Naco Ox delivers a low area-specific resistance (ASR) of 3 mΩ·cm² and superior chromium penetration resistance, optimized for the high temperatures and rigorous demands of solid oxide electrolysis.

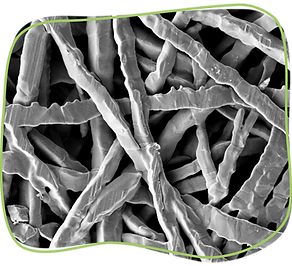

Nickel for Electrodes

By carefully adjusting sputtering parameters NACOs’ researchers have deposited the first samples of nano-road nickel coating. Such well-defined columnar coating can be advantageous for increasing the active surface area for catalyst coatings. Based on these first results a new set of samples will be produces on metallic substrates for catalytic tests.